If you’re exploring metal nameplates for the first time, you’re not alone. Many buyers are unsure where to start: What exactly is a metal nameplate? Why use metal instead of plastic? And how do you choose the right material and process for your application?

At Roemer Industries, we’ve helped manufacturers, engineers, and industrial buyers answer these questions for decades. In this guide, we’ll cover the basics — what metal nameplates are, why they’re used, and how to choose the right type for your application.

What Are Metal Nameplates?

Metal nameplates are durable product identification labels designed to display critical information for the life of your equipment. Unlike paper, plastic, or other materials, metal nameplates are built to survive industrial conditions while remaining legible, reliable, and compliant.

These plates are commonly used to display:

- Compliance and regulatory information

- Safety warnings and instructions

- Serial numbers and model information

- Brand logos, product details, and more

In short, a metal nameplate ensures your equipment is identified, safe, and trackable — no matter the environment.

Why Choose Metal Nameplates?

Industrial identification tags and nameplates must be dependable. Whether installed indoors on a production line or exposed to outdoor conditions, equipment often faces extreme temperatures, abrasion and heavy handling, chemical washdowns, harsh weather conditions, moisture and humidity, and more.

Metal nameplates are specifically engineered to withstand these conditions, keeping essential information intact. Their superior durability makes them the ideal solution for industrial safety, compliance, operational efficiency, and long-term asset management – providing lasting performance and peace of mind.

Once you understand why metal nameplates are preferred, the next step is selecting the right material for your environment.

Selecting the Right Metal Material

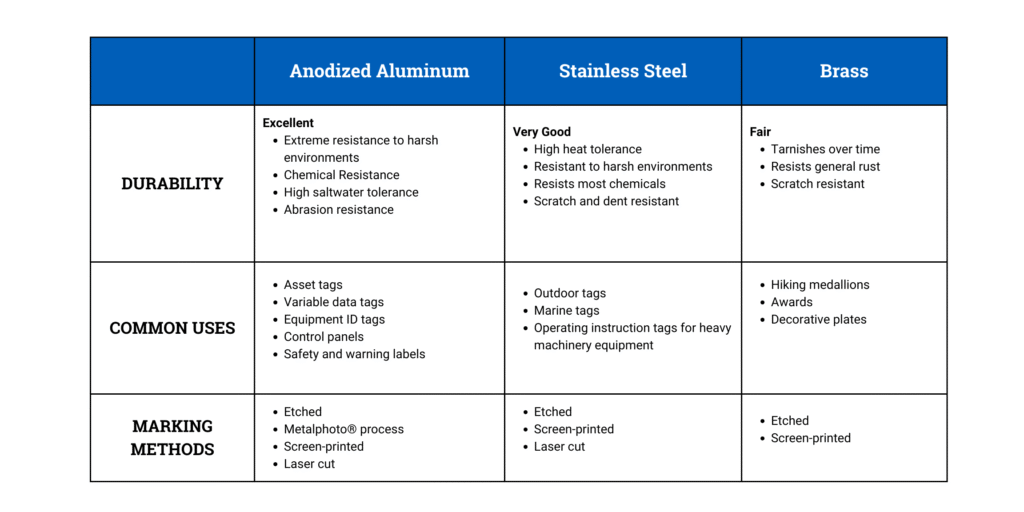

Choosing the right material for your metal nameplates depends on where they will be used and the environmental challenges they may encounter. Common options include:

- Stainless steel: Extremely durable, heat- and corrosion-resistant, ideal for harsh indoor or outdoor environments.

- Aluminum (Anodized and Non-Anodized): Lightweight, versatile, and cost-effective. Anodized aluminum adds scratch and corrosion resistance and works well with detailed graphics.

- Brass: Corrosion-resistant and non-sparking, great for oil and gas or volatile environments. Polished finish adds a professional look.

How Metal Nameplates Are Used in Industrial Environments

Metal nameplates are essential across high-demand industries such as automotive, oil and gas, transportation, OEM manufacturing, and pump and valve production. These sectors rely on durable identification to support product traceability, asset management, operator safety, and regulatory compliance.

Beyond basic labeling, well-designed metal nameplates reinforce your brand—turning each component into a long-lasting, professional touchpoint.

Common uses for industrial metal nameplates include:

- Asset identification & tracking: Serial numbers, model data, and manufacturing details that support inventory control and lifecycle management.

- Operational Instructions: Clear diagrams, lubrication points, and step-by-step guides that reduce downtime and prevent errors.

- Safety and compliance warnings: Permanent, highly visible hazard alerts and regulatory information to protect workers and equipment.

How Information is Applied to Metal Nameplates

With a clear understanding of the nameplate’s function, its importance, and the ideal material for your industrial application, the next step is examining how the information is applied to the tag. The manufacturing process you select directly affects durability, clarity, and long-term performance.

Different metals support different marking methods, but the most common—and most reliable—processes include chemical etching, screen printing, and Metalphoto. Each offers unique advantages depending on your environment, the level of detail required, and the lifespan of the equipment.

Common information application methods include:

- Chemical Etching: Uses controlled chemical processes to remove material and create recessed characters or graphics. This method offers excellent durability and can be left unfilled for a natural etched look or filled with color for added visibility. Ideal for harsh or abrasive environments.

- Screen printing: This process applies ink to the metal surface through a mesh screen. Screen printing is a great choice for multicolor logos, detailed graphics, or complex instructional elements in moderate environments where high visual clarity is required.

- Metalphoto®: This is the most durable identification method available. It works by exposing photosensitive aluminum to create an image that becomes sealed beneath a clear protective anodic layer. This embedded design is virtually impervious to chemicals, UV exposure, corrosion, and extreme abrasion—making these metal nameplates capable of lasting 20+ years, even in the harshest environments. (Note: This process is exclusive to aluminum)

How to Choose the Right Metal Nameplates for Your Application

Choosing the right metal nameplate isn’t automatic—it requires careful consideration of how the tag will function and the environment it must withstand.

Instead of guessing, rely on our expertise to guide you.

Download our quick-reference guide below to make a confident, informed decision for your metal nameplate application.

Once you know your application requirements, partnering with a metal nameplates manufacturer who understands industrial environments is essential.

Roemer Industries: A Trusted Manufacturer of Metal Nameplates

Choosing the right metal nameplate doesn’t have to be complicated—but getting it right makes all the difference for durability, compliance, and brand impact. At Roemer Industries, we combine decades of experience with precision manufacturing to create custom metal nameplates tailored to your exact needs.

You can rely on our proven experience and commitment to quality:

- Decades of Expertise: With more than 80 years as a custom nameplate manufacturer, we bring unmatched industry knowledge to every project.

- Certified Quality Assurance: As an ISO 9001:2015 Certified company, our processes—from initial consultation to shipment—are tightly controlled and regularly audited to ensure dependable, repeatable quality.

- Regulatory Compliance Ready: We are a UL-authorized and ITAR-approved supplier, ensuring your metal nameplates meet essential federal, safety, and industry requirements. Certificates of Conformance and material certifications are provided upon request.

Our team is ready to answer questions and guide your project every step of the way. Contact us today to get started on a custom metal nameplate built for durability, compliance, and lasting impact.