Have you examined your equipment nameplates lately?

For industrial equipment, a nameplate is more than just a way to label equipment — it is a critical safety component, a maintenance record, and for some, a legal requirement.

There is a frustration that most manufacturers, production managers, and plant engineers come face-to-face with at some point: the “ghost” plate. This is a nameplate that has faded, peeled, or corroded until it is completely unrecognizable.

What Causes Nameplates to Fade

Before you can find a solution to your fading equipment nameplates, you have to know what is causing the issue. Take a look at some of the most common factors that affect nameplate readability:

- UV Light Exposure Damage

Most printed labels use low-grade inks that rely on organic pigments that simply can’t stand up to the sun. Over time, ultra-violet light rays break down these pigments, causing colors — especially red — to fade. The metal might still be there, but the text is gone, leaving your nameplate unreadable and your equipment vulnerable.

- Chemical and Solvent Abrasion

In industrial settings, equipment is often hosed down with harsh cleaning agents, degreasers, and other compounds. If the text is sitting on top of the metal, these chemicals act as paint thinners, wiping the information away after multiple exposures.

The text looks smeared or wiped off, particularly around the edges.

- Moisture and Salt Corrosion

Not all metals perform the same in harsh environments. In marine or high-moisture conditions, salt-laden air creates a battery-like reaction between the plate and the equipment surface. This leads to pitting and “white rust” on aluminum, and tea-staining on low-grade stainless steel.

Over time, the tag’s surface becomes rough, flaky, and coated with a white residue, making it look corroded and worn.

Why Ignoring Faded Equipment Nameplates is Not the Solution

Replacing equipment tags takes time and effort, but the payoff is worth it. At Roemer Industries, we can help you find a permanent tag solution. Ignoring those cracked, faded, and worn-out tags carries a much higher price tag than you realize.

Here’s the hidden price of neglected equipment nameplates:

- Poor Brand Reflection

When end users see worn-out, unreadable tags on your equipment, it sends the wrong message about your company and products.

Faded tags suggest neglect, poor maintenance, and a lack of attention to detail – qualities no company should want associated with its brand. Even if your operations are top-notch, the appearance of your equipment speaks volumes.

Clear, durable equipment nameplates show professionalism and reliability, and create a trusted look for not only your stakeholders, but your workers.

- Safety Risks

If compliance is critical in your industry, you need equipment that you can rely on. When tags fade, vital information becomes unreadable, creating serious safety risks. Operators who can’t see load limits, voltage ratings, load limits, or warning details are left guessing.

Without this key information, mistakes are bound to happen. The wrong part number might get installed, maintenance could be delayed, or workers themselves could get into serious accidents if the equipment is operated outside of safe limits.

Errors increase the risk of injuries, accidents, and create downtime, which in turn can cost you greatly.

Now that you understand the common causes of nameplate damage and why it’s important to address them, let’s look at proven solutions to keep your equipment tags clear, durable and compliant.

Protect Your Brand with Permanent ID Solutions

If your current plates are fading, chances are they were made using surface-level printing methods. To achieve true permanency, you need a process that embeds the information into the material itself – making it resistant to wear, chemicals, and harsh environments.

Here are the three proven solutions to stop fading for good:

- Metalphoto® (Photosensitive Anodized Aluminum): Metalphoto is the most durable print process in metal plate manufacturing. It works by exposing photosensitive aluminum to create an image that becomes sealed beneath a clear protective anodic layer. This means that your text, logo and vital information is protected under a hardened layer, and can’t be easily scratched off.

This embedded design is virtually impervious to chemicals, UV exposure, corrosion, and extreme abrasion — making these metal nameplates capable of lasting 20+ years, even in the harshest environments.

- Chemical Etching: Etching of metal uses controlled acids to remove material and create recessed characters or graphics. This method offers excellent durability and can be left unfilled for a natural etched look or filled with color for added visibility.

- Laser Cutting (like a stencil): Guided by digital precision, it involves a CNC System that sweeps across the metal, cutting through each piece for finely cut metal shapes.

How to Choose the Right Print Process for a Permanent Tag Project

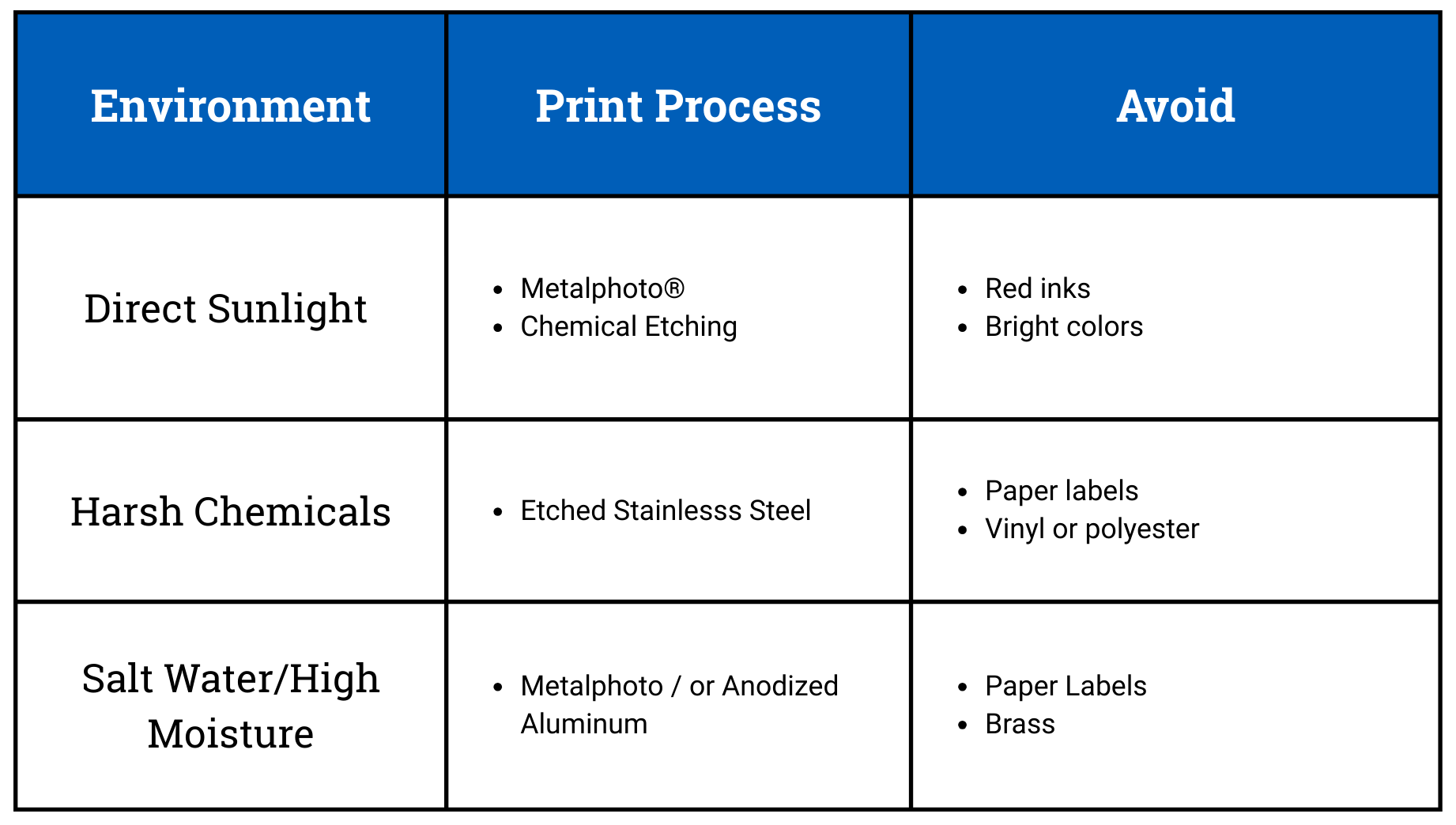

Selecting the right print process is critical to ensuring your equipment tags last. It starts with understanding the environment they’ll face and choosing materials that can withstand those conditions. That’s where Roemer can help.

We specialize in custom metal tags built for durability and compliance.

Download our quick chart to be sure of the correct print process.

Our team is here to ensure your nameplate project is seamless from start to finish. Contact us to help you replace those faded, worn-out tags and protect your brand integrity.