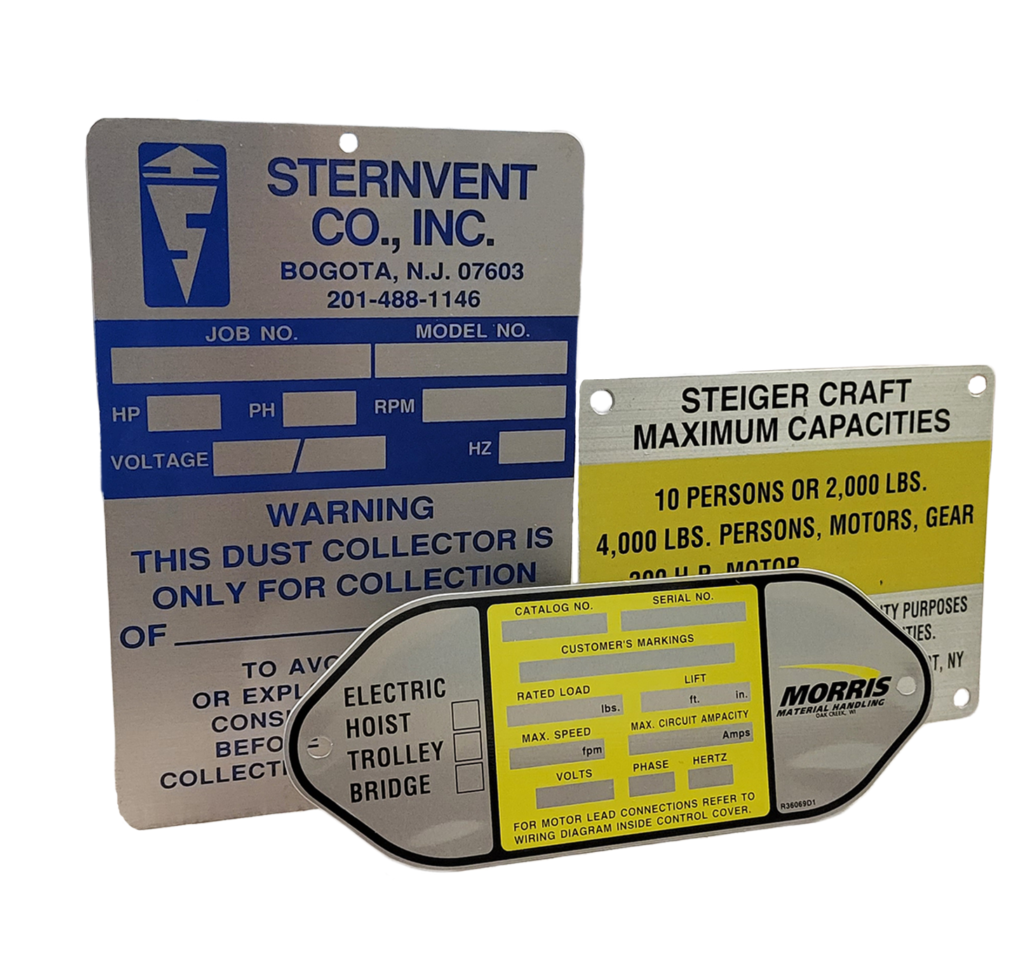

At Roemer, we manufacture a multitude of custom identification products. We want to highlight tag options that are perfect for applications where durability is paramount. Curious about the most durable metal nameplate?

The durability will ultimately depend on your environment.

Before requesting a custom quote from Roemer, consider the environment your nameplate will face. What surface will it be on, and how will it be attached? These are key questions to answer for optimal performance for your specific tagging needs.

Now that you know your environment is a critical factor when requesting a custom nameplate, we can look into the type of metal substrates available and their varying levels of durability.

- Stainless Steel Nameplates

Stainless steel has the highest tensile strength, scratch resistance and heat resistance of any nameplate material. Guaranteed to last your products’ lifetime, a stainless steel nameplate will outlast traditional paper labels and will hold up well in harsh, industrial environments.

Stainless steel nameplates are well suited for these industries:

- Manufacturing: holds up well in dirt, grease and extreme temperatures; they are best on machinery, tools and other equipment.

- Construction: able to withstand weather and abuse; perfect for warning and safety labels and equipment identification.

- Energy: they can be used in power plants, refineries and other facilities that are exposed to chemicals.

- Aerospace: stainless steel handles the demanding conditions of flight, vibrations and chemicals; they are best used on aircraft parts, instruments and tags.

- Automotive: Because of their high-heat resistance, they are able to withstand intense temperatures under the hood, making them ideal for engine component tags and trailer tags.

2. Metalphoto® Aluminum Nameplates

Arguably one of the most durable substrates for a metal tag, metalphoto® aluminum holds up extremely well under severe conditions like snow, ice, heavy rain and other environmental factors. It won’t fade in extreme sunlight, holds up well in heat, and is resistant to chemicals, ensuring the tag information never fades. It is also scratch and abrasion resistant, and offers the best scanning abilities for QR and barcode applications.

Metalphoto® tags are well suited for:

- Marine applications: salt spray and UV rays aren’t a problem for this durable tag.

- Electrical environments and transformers: perfect for tagging areas where a barcode or QR code is required.

- Oil/Gas Industries: heavy operating equipment for material handling.

- Mining Equipment

- Transportation: rail, buses and other freight equipment.

3. Aluminum Nameplates

Known for its shiny surface, aluminum is another great candidate for a metal nameplate solution. Aluminum is lightweight and durable, and when anodized, is highly resistant to damage from sources of abrasion and other hazards. It can be printed in a wide range of colors and thicknesses, and is slightly more cost effective than steel.

They are more suited for indoor appliances due to their lightweight properties, including: furniture, consumer goods, sporting equipment, and other equipment that isn’t exposed to a lot of harsh, outdoor conditions.

4. Brass Nameplates

Brass withstands weather conditions like heat and cold, and is corrosion-resistant. Brass has a natural golden tone that makes it attractive and noticeable, making it another great candidate for marine applications, and outdoor environments.

Brass tags are well suited for:

The key to a long-lasting nameplate lies in selecting the ideal material for its environment. Consider the surface you’ll be attaching it to – is it indoors or outdoors? Will it be exposed to extreme temperatures or harsh chemicals? By understanding these factors, you can choose the best material for the job.

Still unsure of which material is best for your needs? Use the link below to request samples from Roemer Industries to see for yourself!